Heat pump systems are an all-electric option for heating and cooling needs that offers many benefits, including options for zoning and heat exchange between spaces to improve comfort and efficiency. Paired with renewable energy, heat pump systems can achieve carbon neutral status, while providing space conditioning for many types of commercial facilities, such as office buildings, hotels, schools, houses of worship, and historical buildings.

Heat Pump Technology and Options for Commercial Heating and Cooling

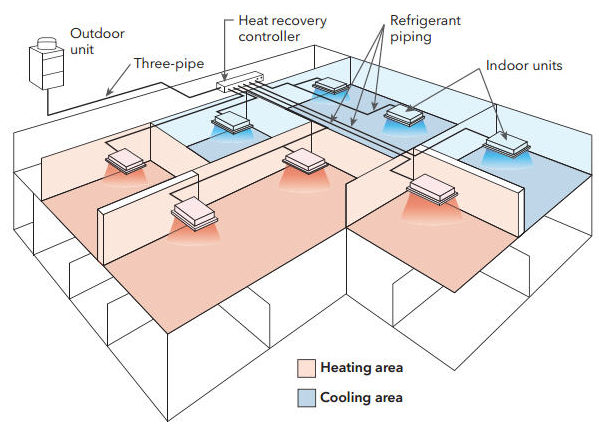

Variable refrigerant flow heat pump systems can deliver cooling to some zones and heating to others simultaneously. Image credit: www.seventhwave.org

Variable refrigerant flow heat pump systems can deliver cooling to some zones and heating to others simultaneously. Image credit: www.seventhwave.orgAbout Heat Pump Technology

A heat pump system transfers heat energy between the building and a thermal reservoir outside of the building. The thermal reservoir can be the air, water or ground, and heat is transferred from the higher temperature zone to the lower temperature zone. Heat pumps can deliver one-and-a-half to three times more heat energy to a building than the electrical energy that it consumes. This is possible because a heat pump moves heat, rather than converting it from a fuel like combustion heating systems do.

In addition to space conditioning, heat pumps have the ability to heat water and clothes driers. A kitchen refrigerator is basically a heat pump that transfers heat in only one direction.

In cold weather, a heat pump system provides warm air by transferring heat from outside to inside the building. The process is reversed in warm weather to provide cool air by moving heat from inside of the building to outside.

There are three major categories of heat pump systems: air source, water source and ground source.

- Air source heat pumps exchange heat between the air inside of the building and outside of the building and are available in packaged or split system units. Air source heat pumps are less expensive to install than water or ground source systems, but can be less efficient in cold conditions. Heat pumps with an efficiency rating of 9.00 HSPF (heating) and 16 SEER (cooling) or higher is recommended for cold climates.

- A water source heat pump system operates by exchanging heat with water instead of the air. These systems can pair with either a mechanical method of rejecting heat (such as with a cooling tower) or with a natural source of heat exchange (such as a lake or reservoir).

- Ground source heat pump systems are becoming increasingly popular as a reliable year-round source for heating and cooling in cold climates. A ground source heat pump system utilizes the constant temperature of the ground, exchanging heat between the Earth and the building via a series of ground loops. Ground source heat pump systems require extensive space to run the ground loops that can be either horizontal or vertical systems. The appropriate type is determined by the ground conditions and available space.

Heat pumps offer many options for meeting heating and cooling needs, and because they are electric, a heat pump system can be paired with renewable energy to reduce greenhouse emissions and improve your business’ environmental footprint.

- Paired with renewable energy, heat pump systems can be a step toward achieving carbon neutrality by reducing greenhouse gas (GHG) emissions associated with gas-fired equipment.

- Heat pump systems can be ducted or ductless systems, which can be beneficial depending on the unique attributes of a facility. Heat pumps can utilize existing ductwork, or ductless heat pump systems can be installed in scenarios when adding duct runs would be challenging and/or costly.

- Variable Refrigerant Flow (VRF) heat pump systems are capable of additional energy savings through heat recovery.

- Heat pumps can be paired with gas in dual fuel systems for extreme cold climates.

- Heat pump systems can provide space conditioning needs using various thermal reservoirs, such as the air, water, and ground (Earth’s natural heat sink).

- In addition to space heating and cooling, some heat pump systems can also provide water heating.

- High-efficiency heat pump systems are available.

- Heat pumps can increase occupant comfort by allowing individual spaces to be zoned to manage their own separate heating or cooling needs.

No. Heat pumps are a conventional technology that have been around as early as the 19th century. Heat pump systems have been an option for heating and cooling in the United States for over thirty years, continually improving in technology and efficiency.

Both use compressors and refrigerant and transfer heat from inside to outside of the building; however, heat pumps are different in that they can reverse this process, thereby having the capability to provide both cooling and heating.

Natural gas systems were historically the preferred choice in cold climates, due to loss of heat pump efficiency at temperatures below 40 degrees. However, newer heat pump models are better equipped to manage low temperatures; some now operate efficiently down to 20 degrees. In freezing temperatures, heat pumps use resistance heat (emergency mode), which is an energy penalty (loss of efficiency).

Ground source heat pump systems are often referred to by equipment manufacturers and the building industry as geothermal systems. This can cause confusion with the geothermal energy systems that some industrial-scale facilities use that exchange heat directly from natural sources like hot springs, geysers and volcanic hot spots to generate electricity or provide steam for heating.

A VRF heat pump system, sometimes referred to as the industry trademarked term VRV (Variable Refrigerant Volume), uses refrigerant as with other heat pumps; however, a VRF system can simultaneously heat and cool, and also has the capability to provide heat recovery. A single outdoor condensing unit operates multiple indoor evaporator units serving various zones, controlling the amount of refrigerant flowing to each. Each zone is therefore able to manage its own temperature, heating or cooling.

- These systems can be well-suited for buildings that are comprised of smaller spaces, such as office buildings or multiple story buildings with lots of glass, where adjacent spaces may have different heating and cooling needs.

- VRF systems have the capability to provide heat recovery, by capturing heat from one space and redirecting it to another.

- VRF systems can be more costly than conventional gas/electric systems, and the amount of refrigerant runs required to manage the flow to/from controls requires careful planning and design.

- VRF heat pumps with an HSPF of 9.00 and SEER 16 or higher is recommended for cold climates.

Similar to air source heat pumps, which heat and cool the air in your building, heat pump water heaters extract heat from the air and transfer it into a tank. Most heat pump water heater heat pump components are located within the building interior and combined with the storage tank. Heat pump water heaters are typically 2-3 times more efficient than electric resistance water heaters.

A dual fuel system is primarily a heat pump that switches to gas or oil to supply heat in extreme cold conditions (usually less than 35 degrees). Larger packaged heat pump systems typically have this combination of energy sources to meet heating demands in cold climates.

Often the two systems are referenced interchangeably and together; such as “ductless”, “mini-split” and “ductless mini-split”.

- A ductless system utilizes a ceiling or wall-mounted indoor evaporator unit, requiring only refrigerant lines to connect to an outdoor condenser – therefore, no ductwork.

- Mini-split is a term often used to describe the system that is not ducted (ductless), where a single outdoor condensing unit is paired with a small, single indoor evaporator unit to provide cooling (and in some cases heating).

- “Split” system refers to a system where part of the system, the compressor and condenser coil, is located outside of the building, and part of the system, the evaporator coil and air distribution, is located inside of the building.

Heat pump systems are available in ducted and ductless systems. There are benefits of each type, depending on the building configuration, age, and space cooling and heating needs.

- Ducted systems can conveniently provide heating and cooling, and often provide required fresh air supply to a building. Ductwork can be hidden for aesthetics within ceiling and/or wall cavities and are best at managing larger spaces with consistent loads and space conditioning needs. These systems include an outdoor condensing unit connected to an indoor evaporator (air handling unit) and building ductwork that distributes cooling and/or heating throughout the building.

- Ductless systems reduce the need for additional duct runs and are often wall-mounted. Some ceiling-mounted versions are available for drop ceiling applications that are more aesthetically pleasing. Ductless systems can be installed as a primary source of heating and cooling or installed to supplement existing systems. It is important when choosing a ductless option to ensure commercial ventilation requirements are met.

Most major HVAC companies manufacture some type of heat pump system. The following are some heat pump manufacturers, in alphabetical order, and are not inclusive of all manufacturers that offer heat pump systems.

- American Standard

- Bosch

- Carrier

- Daiken

- Fujitsu

- Lennox

- Mitsubishi Electric

- Panasonic

- Samsung

- TRANE

Important Considerations Regarding Heat Pump Technology

Heat pump efficiency can drop in extreme low-temperatures, depending on the system type, size and location. In below-freezing temperatures, heat pumps use resistance heat (emergency mode), which is an energy penalty (loss of efficiency).

To increase performance relative to your building’s space heating and cooling needs, consider the following when purchasing heat pumps:

- Staged compressors, such as 2-speed compressors that are better at managing heating/cooling in spaces of varying occupancy and can be more efficient by not over-conditioning

- Select higher efficient equipment with Energy Efficiency Ratings of an HSPF (Heating) of 9 or greater, and an SEER (Cooling) of at least 16 or greater.

- Consider decoupling the ventilation system from the heating and cooling system and bringing in fresh air separately. This allows for “free” cooling on days when the outdoor air temperature and humidity are optimal for space conditioning.

As with any other HVAC system, there is a series of maintenance schedules required to ensure performance and reliability. Inspections of refrigerant runs and connections are important to maintain equipment efficiency, but also are important to avoid leakage due to lack of maintenance, which can have a detrimental environmental impact.

Aside of regularly scheduled maintenance, it is recommended that buildings with advanced heat pump systems (such as VRF systems with heat recovery or ground source heat pump systems) are recommissioned every 3-5 years to ensure they are operating as intended.

- Energy Recovery Ventilation (ERV)

- Heat Recovery Ventilation (HRV)

- Dedicated Outside Air System (DOAS)

- Air handler unit (AHU) connected to variable refrigerant flow (VRF) system

Upfront equipment costs for heat pumps are typically higher than conventional heating and cooling units; however, the cost can be mitigated with proper planning for major building upgrades. Ongoing operating costs are also generally higher.

Heat pumps rely on electric energy and pair well with renewable sources, which may help mitigate peak demand charges.

Look for ways to reduce upfront costs through available rebates and incentives.

VRF systems – with or without heat recovery require careful planning and design for refrigerant runs between the outdoor and indoor units.

Ground-source systems require significant space to run the geothermal loops.

Ventilation requirements are applicable to all commercial buildings – consider space and locations of duct runs in order to supply fresh air needs for space-use type and occupancy load.

Use appropriate equipment to meet space heating/cooling needs:

- Small, zoned areas and large areas typically require different system types.

- Small areas can pair well with zoned systems, such as variable refrigerant flow (VRF) systems.

- Larger single zone areas may require a system that can perform well in varying conditions, such as retail stores, when occupancy can change from just a few people to a large occupancy load. In such conditions, a staged air-source heat pump (hyperlink) or multiple units may be required to meet the space needs.